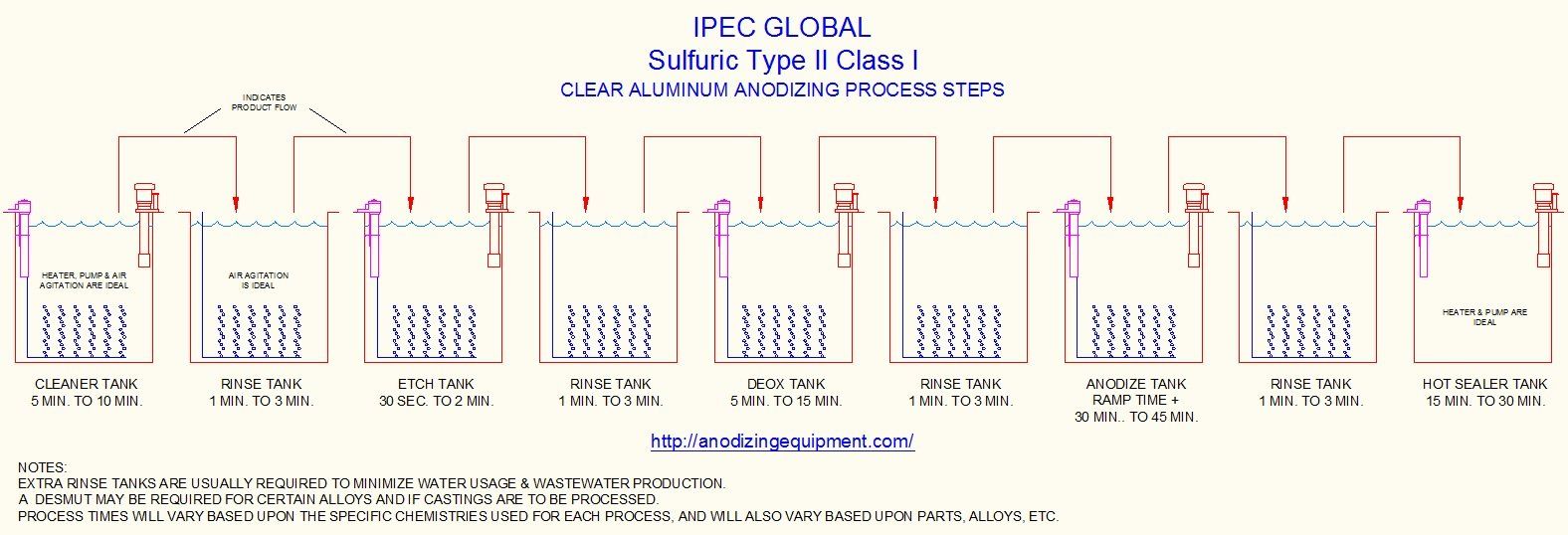

How to Anodize Aluminum

Industrial Aluminum Anodizing

New Extra rinse tanks are usually required to minimize water usage U wastewater production a Desmut may be required for certain alloys and if castings are to be processed. Process times will vary based upon the specific chemistries used for each process, and will also vary based upon parts, alloys, etc.

How to Anodize Aluminum Step 1

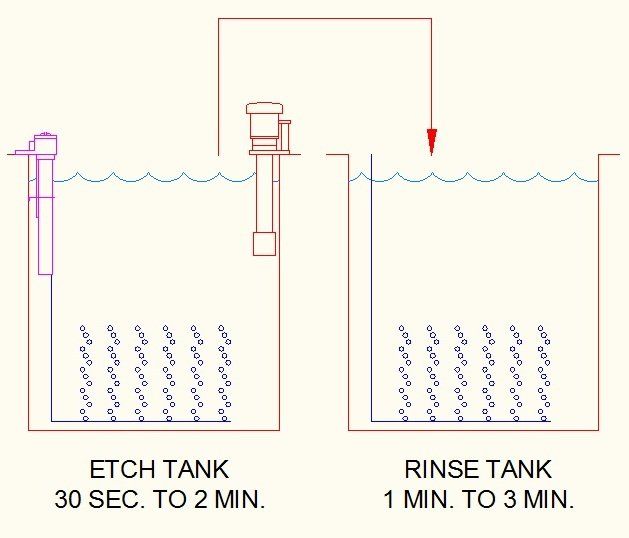

How to Anodize Aluminum Step 2

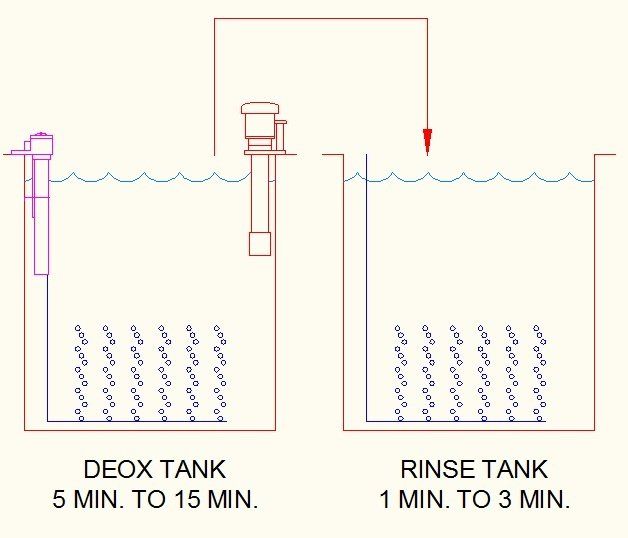

How to Anodize Aluminum Step 3

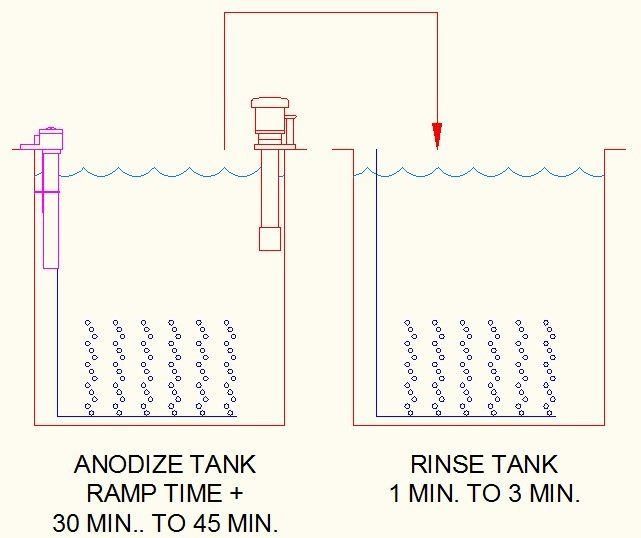

How to Anodize Aluminum Step 4

How to Anodize Aluminum Step 5

NOTE:

How to anodize aluminum as per Mil-A-8625 or Type II Class I is specific to clear sulfuric acid anodizing, but is also a general overview of a “typical” anodizing procedure. Type II Class II (dyed or colored aluminum anodizing) is the same process as above, but with color dyes right after the anodize step, and to maintain colorfastness in the dyed anodic film, a nickel acetate or dichromate seal is usually used instead of a hot DI seal.

Note that different chemical suppliers will probably call out different process times, and many customers (especially aerospace or aircraft manufacturers) may have different process parameters and / or preferred chemicals and vendors, so if you are considering having an aluminum anodizing line designed for your specific needs, the types of parts and your key customers may be an important factor to consider. How to anodize aluminum may vary slightly based upon these considerations, but not substantially.

by Mark Emilio