CHEMFILM

Adding Chemfilm Processing to Your Facility

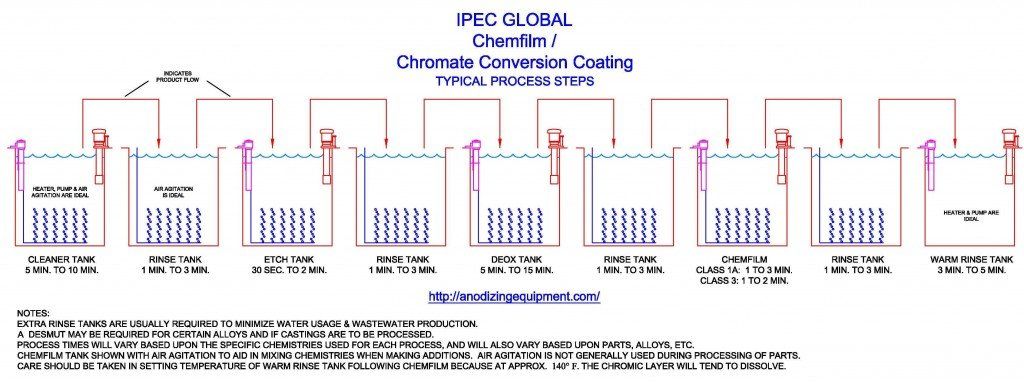

A brief description of the steps involved in the typical Chemfilm procesragraph

Extra rinse tanks are usually required to minimize water usage & wastewater production. A desmut may be required for certain alloys and if castings are to be processed. Process times will vary based upon the specific chemistries used for each process, and will also vary based upon parts, alloys, etc. Chemfilm tank shown with air agitation to aid in mixing chemistries when making additions. Air agitation is not generally used during processing of parts.

Care should be taken in setting temperature of warm rinse tank following chemfilm because at approx.. 140 degrees F. The chromic layer will tend to dissolve.

ADDING CHEMFILM PROCESSING TO YOUR FACILITY

Stand-Alone Chemfilm line w/ closed-loop

This is a stand-alone chemfilm line with closed-loop I/Xagraph