Anodizing Kits

Wastewater Treatment - Pollution Control

Many of the people who happen onto one of our websites looking for anodizing or plating equipment are really more interested in very small “anodizing kits” rather than the larger anodizing lines that we usually design and build. Many of them will then ask us what the differences are between the anodizing kits and larger anodizing lines, and whether a customer could do the same anodizing in the small “kit” tanks as the larger anodizing houses do in much larger tanks.

The short answer to the last question is “yes” because with few exceptions, you can do the same anodizing processes in the anodizing kits that the larger anodizing firms do in big industrial lines. Given that, why would somebody spend so much to buy an industrial anodizing line when they can do roughly the same job in anodizing kits? The answer to this question goes back to those differences between the anodizing kits and the larger industrial anodizing lines.

Process Differences in Anodizing Kits

Most plating and anodizing kits are designed around keeping the price down as low as possible (so people will buy them), and in doing so, a lot of functional compromises are made and process corners are cut. Among these items are things like not providing enough rinses, having static rinses instead of running rinses, using tap water instead of D.I. water, not having automatic controls like ramps built into the rectifiers, not allowing for air or solution agitation (via spargers or diffusers) or filtration of solutions, and in some cases the price is lowered by skipping processes completely.

Process Chemistries for Anodizing Kits

Some of the higher-end industrial anodizing shops do work for Aerospace companies like Boeing, Airbus, or Cessna, and because of the importance of the anodizing quality for these customers and their parts, these anodizing shops buy special proprietary chemistries that are not available to “average” users, especially those with tank volumes like what you would find in anodizing kits. These proprietary chemistries can often give better performance than conventional chemistries, but even more importantly, buying them provides the specialized technical support that only those chemical suppliers can offer. Having that support can not only give a company a great competitive edge, but might also make the difference between succeeding in anodizing or not. The chemicals provided with anodizing kits are typically more generic in nature so they may or may not provide the same process coverage, performance or thickness as their costlier counterparts.

Process Repeatability in Anodizing Kits

Largely because of the differences already stated, but also because of the smaller tank volumes usually found in anodizing kits, the ability to provide the same finish on the same parts time and time again is much less in anodizing kits than it is in larger industrial tank lines. Why does tank volume matter? Let’s say that your parts were to need to “use up” one tenth of an ounce of acid to do the anodizing process. When you make up your process chemistries, you make them up by putting together a certain concentration of the chemistry, usually in water. If we “use up” one tenth of an ounce of acid by processing your parts, and if we only have a half gallon of process chemistry in the anodizing kits tank, then that one tenth of an ounce of acid will make a pretty big difference in the concentration within that tank. If you were to use up the same one tenth of an ounce, but this time out of a 100 gallon tank, that one tenth of an ounce would probably not make a measurable difference in the concentration within the tank.

New PAn IPEC tabletop plating or anodizing kitaragraph

New An IPEC tabletop Aluminum Anodizing system for NADCAP approval

Why Consider Anodizing Kits

Why even consider anodizing kits? First of all, anodizing kits are much cheaper than an industrial anodizing line. Second of all, it is a very cost-effective way to “get your feet wet” if you are considering bringing anodizing into your facility. It can also be used effectively as a stand-alone processing system, provided you are aware of many of the shortcomings and can compensate for them. Remember, too, that smaller anodizing kits can be “grown” into a larger system piece by piece as needed, so they can become the larger system you need as you need it.

Real Production, Small Lines

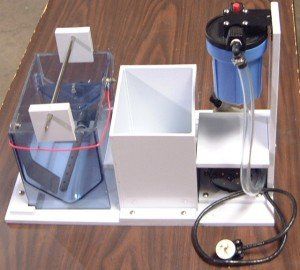

If your parts are small and your production numbers are low enough, you can do “real” anodizing with a “real” ventilation system with smaller lines like the one in the picture to the left. These types of systems are for customers who need to do real production work with limited space and at lower capital or running costs but who also need NADCAP or other professional approvals. A small line like the one shown starts at about $30,000 complete (for type 2 class 1 aluminum anodizing).

by Mark Emilio